The Greatest Guide To Non Woven Fabric Making Machines

This consistency is essential, particularly in industries where non-woven fabrics are employed for health-related supplies, guaranteeing that merchandise meet stringent top quality requirements.

The adoption of PP spunbond nonwoven fabric making machines provides forth several strengths more than conventional manufacturing procedures. These positive aspects involve:

Tools and machinery makers must give attention to shielding their workforce, operations, and supply chains to respond towards quick crises and obtain new means of working following COVID-19

Thick nonwoven fabrics also can be making from flax fibers by needle punching system. The retted, scutched, and hackled flax fibers are well suited for needlepunching with or with no chemical therapy.

● Our tests personnel will debug and test it for non woven bag manufacturing when your non woven bag machine is ready.

This examine provides the analytical depiction in the as non-woven fabric making machine industry together with the recent tendencies and future estimations to determine the future of the marketplace

Nonwovenmanufacturing is usually explained in simple conditions like a number of manufacturingsteps consisting of forming a fibrous Net, entangling or bonding the fibres inthe web to impart mechanical integrity on the framework andfinishing/converting the fabric to impart some Unique Attributes into the fabricthat The shopper specifies. The manufacturing measures are explained beneath:

The most often applied binder is latex, since it is affordable, straightforward to use and very successful. Quite a few procedures are utilized to apply the binder and contain saturation bonding, spray bonding, print bonding and foam bonding.

Alternative parts from Reifenhäconsumer Enka Tecnica are absolutely appropriate with all globally mounted meltblown and composite lines. Germany-dependent Reifenhäuser Enka Tecnica focuses primarily on custom made-developed substitution intelligent spinning beams, cassettes and spinnerets which have been compatible with any current spunbond or meltblown line. Its capabilities allow a producer to upgrade present traces and enter new markets together with hygiene, health care or filtration. Enka Tecnica studies the superior caliber on the nozzle guidelines and capillaries guarantee reliable merchandise high quality and precision.

Our non-woven fabric slitting machines are intended to procedure just about any non-woven substance, ensuring our buyers can course of action the precise forms of solutions necessary of their business. Many of the most common sorts of non-woven supplies our converting equipment can change are:

flat needlefelt. Nonwovens systems may be used to produce an assortment of solutions for an ever-increasing amount of finish works by using.

2. Precision and Regularity: These machines are equipped with Innovative engineering that ensures website specific folding and chopping, causing uniform solution Proportions.

The Thermofix-TFE double-belt press flatbelt laminator from Germany-based Schott & Meissner Maschinen- & Anlagenbau GmbH uses a mix of Make contact with warmth and tension. The item being processed passes in the machine concerning two Teflon™-coated conveyor belts. As soon as heated, the material moves by way of one or more calibrated nip rollers into a cooling place to thermoset the material.

Disclaimer: These guidelines are for informational functions only and they are intended as illustration or typical info only and so are not intended like a ensure or guarantee. IWT assumes no duties in reference to the usage of this details.

Taran Noah Smith Then & Now!

Taran Noah Smith Then & Now! Danica McKellar Then & Now!

Danica McKellar Then & Now! Gia Lopez Then & Now!

Gia Lopez Then & Now! Shane West Then & Now!

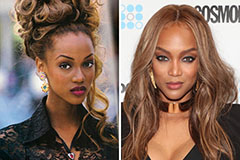

Shane West Then & Now! Tyra Banks Then & Now!

Tyra Banks Then & Now!